The Role of Low-Voltage Transformers in Your Building

As developers and building owners move forward with retrofit projects focused on energy efficiency, the role of low-voltage electrical transformers is attracting more attention as every link in the power distribution system comes under scrutiny for energy efficiency. Low-voltage transformers are the unsung hero in power systems. They work in the background, where they are responsible for power distribution to the entire building. We know from experience that transformers in older commercial buildings, those that are more than 20 years old, are nearing the end of their useful lives and are certain to be less efficient than modern transformers built after the new 2016 Department of Energy* requirements were instituted.

Opportunity Knocks

If you own your transformers (not DTE or another utility), there may be a huge savings opportunity, because replacing transformers can greatly improve energy efficiency. Using high-quality transformers also increases energy resiliency and improves power quality through reduced harmonic distortion (this avoids dirty power and its resulting power interruptions). It is also important to plan for transformer replacements, as opposed to executing emergency replacements, to prevent unwanted downtime and unnecessary safety risks. When specifying a new transformer, there are a few best practices. Like everything else you buy, there is a good, better, and best strategy. First, select ‘high performance’ transformers. Take the time to compare the manufacturer’s test data. Remember, this is an investment that is going to sit there for 30 years or more. Running an inefficient transformer for the next 30 years to save a few dollars up front is guaranteed to be more costly than installing the right equipment the first time.

Next, get support from professionals for testing and verification. If your transformer is over 20 years old, you might want to have it tested for efficiency/operating losses so you will have a baseline to compare projected savings once a new one is installed and measured. Energy efficiency projects are often designed to be financed through the energy savings. Not all transformers are the same. High-efficiency transformers can often pay for themselves through energy savings in a few years.

In a typical power distribution grid, electric transformer power loss typically contributes to about 10% to 20% of the total transmission and distribution loss. Energy-efficient transformers are therefore an important means to reduce transmission and distribution loss. With the improvement of electrical steel (silicon steel) properties, the losses of a transformer in 2010 can be half that of a similar transformer in the 1970s. With new magnetic materials, it is possible to achieve even higher efficiency. Today’s transformer are even more efficient. While we can’t change the utility transformers, we can change those we own in our buildings for savings and resilience.

Can an Energy-Efficient Transformer Benefit My Building?

Energy-efficient building design practices, including net zero, are becoming the norm as more builders and developers realize the benefits of sustainable and energy-efficient buildings baked in at the design phase. Although focus is often placed on things like LED lighting, smart building controls, insulation, windows, and other methods of energy conservation, very few people are aware of the benefits of energy-efficient transformers. In commercial applications, the electricity delivered to your building is delivered at much higher voltages than it is to residential areas. This means that almost all commercial buildings require multiple transformers to decrease (step-down) the voltage, so that it can be used for heating, cooling, plug loads and processes.

Just to be clear, all transformers waste energy and all of that energy is being added onto your power bill, and then simply disappears either through micro vibrations or heat dissipation when converting higher voltages to lower voltages. As you may already suspect, not all transformers are designed equally, nor do they waste the same amount of energy. Typical transformers are built at high volumes with lower quality, and only just meet the regulated U.S. DOE 2016 efficiency standard. In some cases, these standard issued transformers that just meet regulation still waste 50 % to 75% more energy than they need to. This leads to buildings all across the continent, cumulatively paying billions of dollars in wasted and completely unused energy … for 30-40 years especially when extended beyond useful life.

I first became aware of the importance of transformers as an energy auditor, analyzing why some commercial and industrial buildings have better energy performance than others. My transformer research has led me to those made by Powersmiths International Corp., where energy efficiency is the driving force behind the products they manufacture.Powersmiths transformers are optimized specifically for maximum energy loads. They waste significantly less electricity – on average 80% less electricity waste compared to older transformers and 25% to 50% less energy waste than today’s standard transformers. This efficiency is achieved by focusing on high-quality manufacturing and a proprietary energy-efficient, low-voltage design matched to the building power load. Overall, ultra-efficient, dry-type transformers can offer significantly less electricity waste, resulting in a reduced environmental impact and a lower utility bill.

Powersmiths Case Study

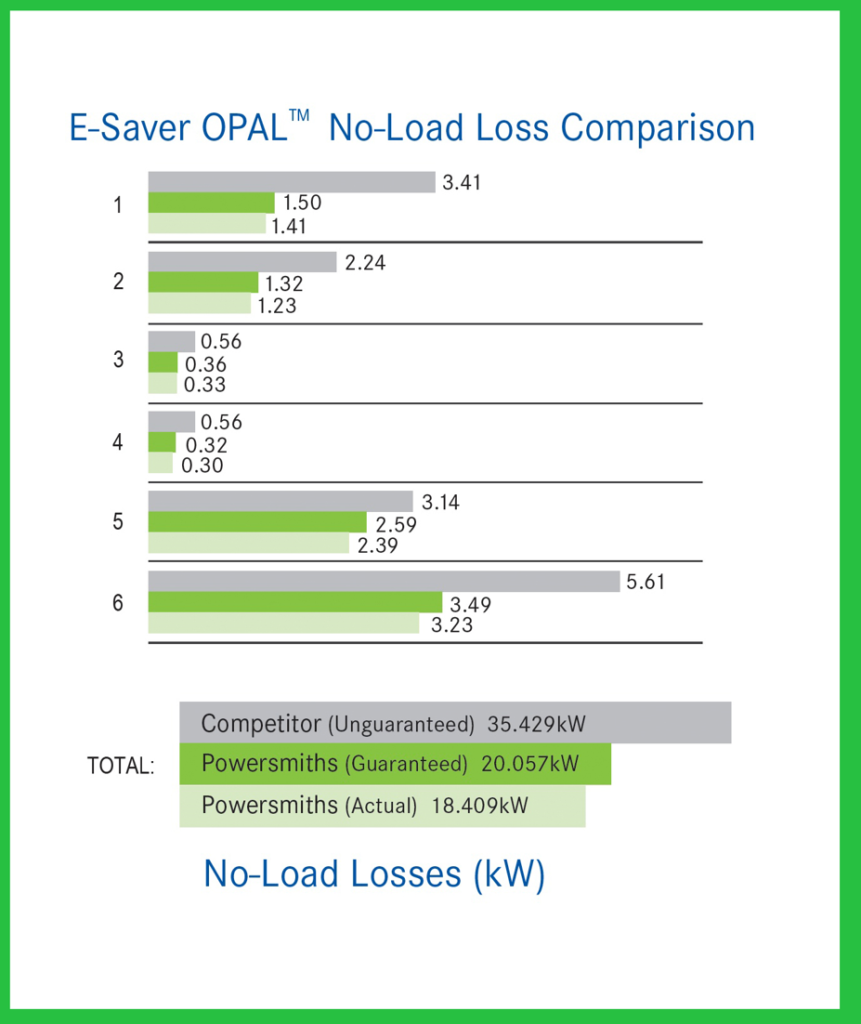

Over the course of 15 months, Powersmiths collected no-load loss data for a commercial office park with 16 buildings and 108 transformers. The no-load loss data was analyzed and compared to Powersmiths’ guaranteed losses per published technical data sheets, as well as the competitor’s published, unguaranteed losses based on the DOE 2016 standard.* Using standardized testing in an ISO 17025 Certified Test Lab, Powersmiths OPAL transformers provided an 8% reduction in no-load losses against their own specifications, and a 48% reduction against the competition’s published data. The illustrated data below represents no-load losses only in a sample of the installed transformers. There are significant additional savings under load with Powersmiths transformers, but this study documents the savings potential 24 hours a day, every day, for the full 32-year transformer lifecycle.

“Powersmiths OPAL transformers, built under ISO14001, deliver substantial energy savings compared to industry standards. As a result, OPAL aligns perfectly with the goals of net zero and sustainably designed buildings – where benefits include lower environmental impact and lower CO2 footprint, through energy and demand cost reduction including a significant reduction in renewable energy offset requirements.”

Mr. Philip Ling

P.Eng., LEED AP, VP Technology

Powersmiths International Corp.

To learn more about transformers or to contact Powersmiths,

please visit www.powersmiths.com or call 1-800-747-9627.

To meet with the Powersmith team at the Net Zero Build Summit see

http://www.netzerobuildsummit.com

* U.S. Department of Energy, 10 CFR Part 431, [Docket No. EERE-2010-BT-STD-0048] Energy Conservation Program: Energy Conservation Standards for Distribution Transformers; Final Rule, April 18, 2013

ElbingerMedia.com is a collaborative of expert marketing, public relations, and media professionals focused on sustainability and the energy space